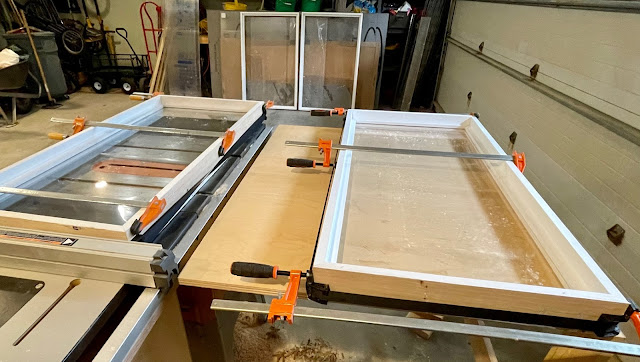

Building Panes

Above are the four panes I built from scratch to fit the weird sized opening. As it turned out, they were neither very time saving or cheap. Evidently acrylic prices have spiked thanks to Covid and unlike lumber prices, they haven't come down much. Also, in the midst of this build, I opted to get my Covid booster and flu shot and suffered a bit for a couple days. But I persevered and got the windows built. They are waiting for glue to dry, need caulking and then I can hopefully work to install them in the next day or so. To make the frames, I started out with some select grade studs so they weren't especially crooked or knotty like building grade studs are. It took me about an hour of table saw work to cut the geometry on them the first time, and another half hour later on when I realized I was two pieces short for my windows, after painting them all. So I ended up with another day of delay in their cutting, painting, and sizing the final two pieces I needed. At least this i